BenchCat Fluid Dispensing Robot Software

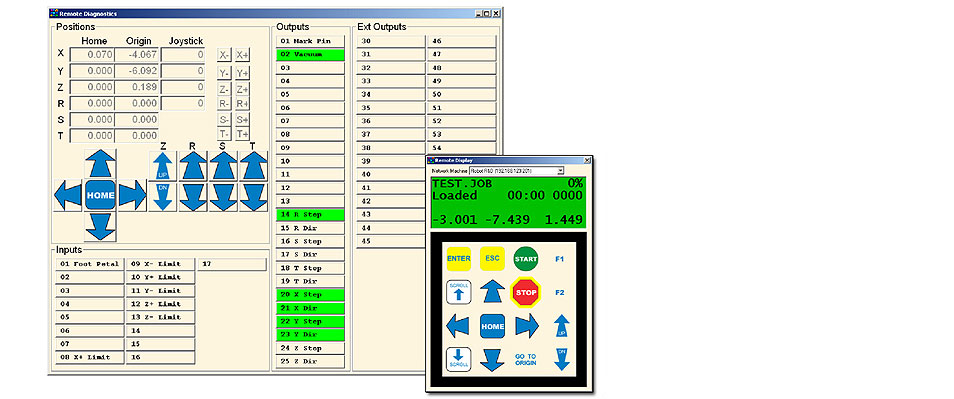

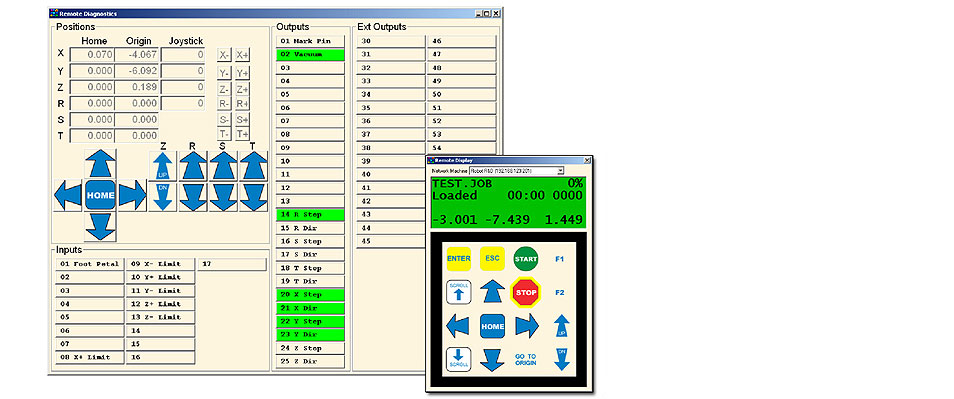

Remote Diagnostics Screen

Read input status, force outputs, and jog machine control for streamlining setup of machines and for trouble shooting.

Operate system directly from the Windows screen and view machine status (parts count, cycle time, etc.) from any remote location.

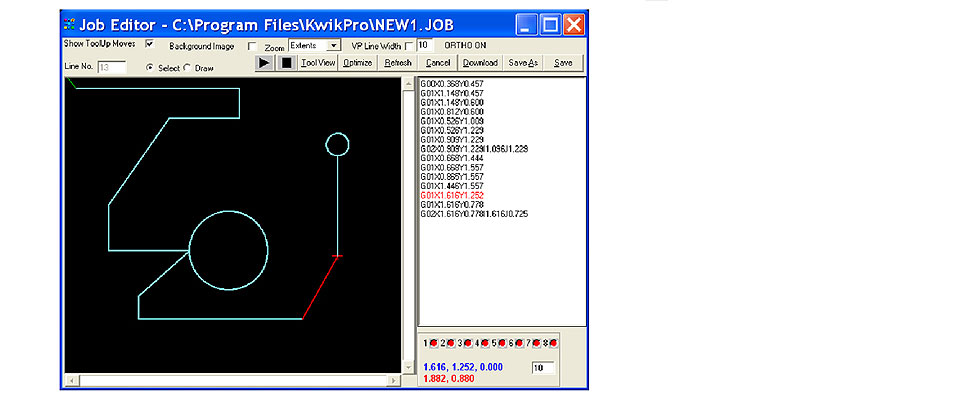

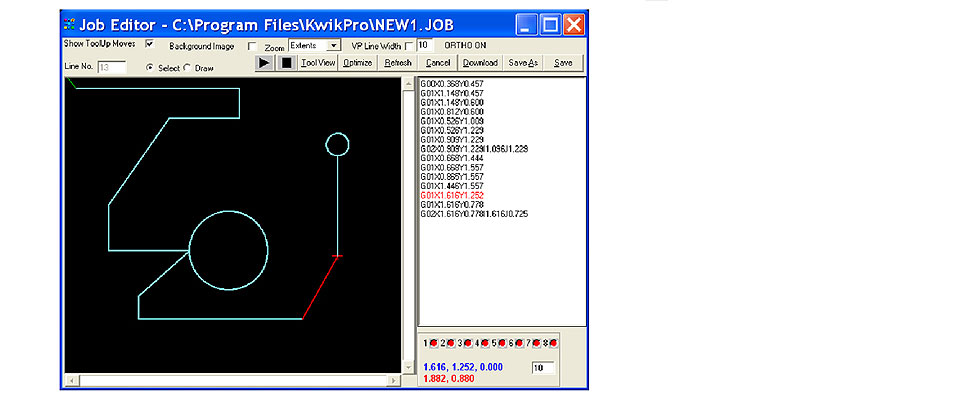

Drawing Tools and Functions

Simple CAD type drawing tools allow user to create tool paths. Use keyboard or teach with the machine.

A background image of your part may be imported to be used as a “template” for 100% graphical machine programming requiring no measuring tools are layout work.

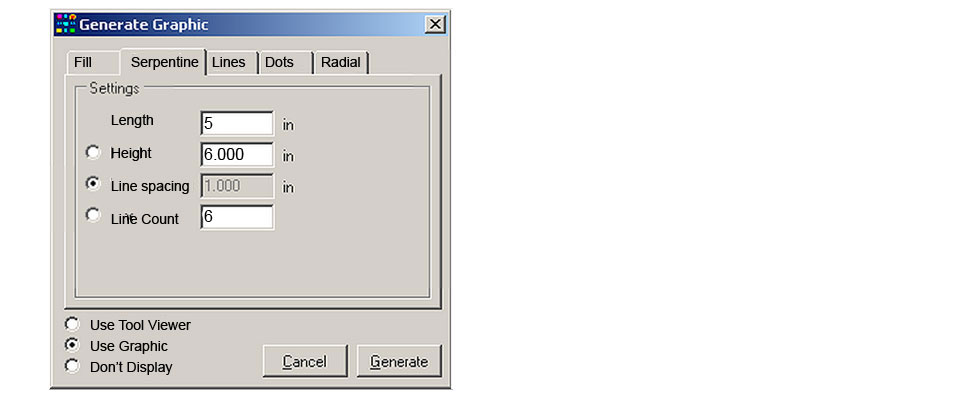

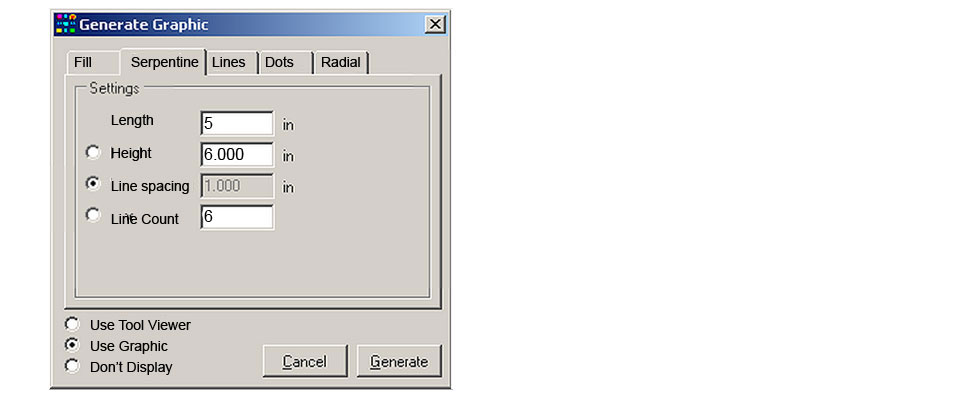

Pattern Generator Function

Automatically create motion paths based on:

Dots

Lines

Serpentine Fills

Square Fills

Radial Fills

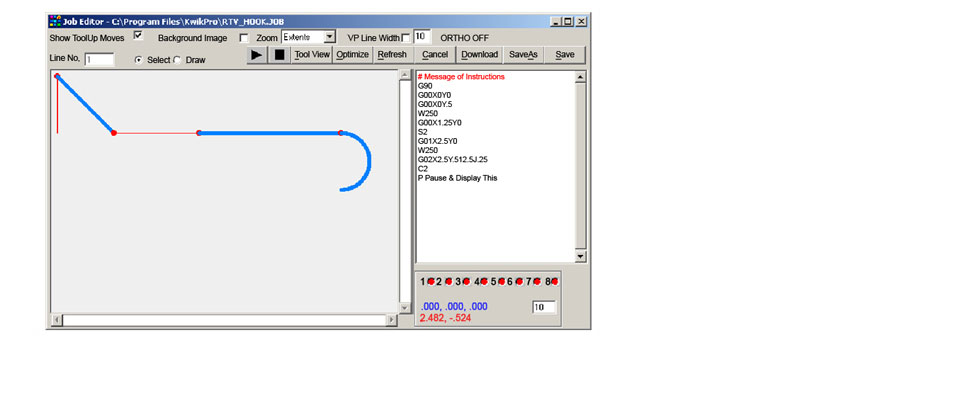

Dynamic Program Builder

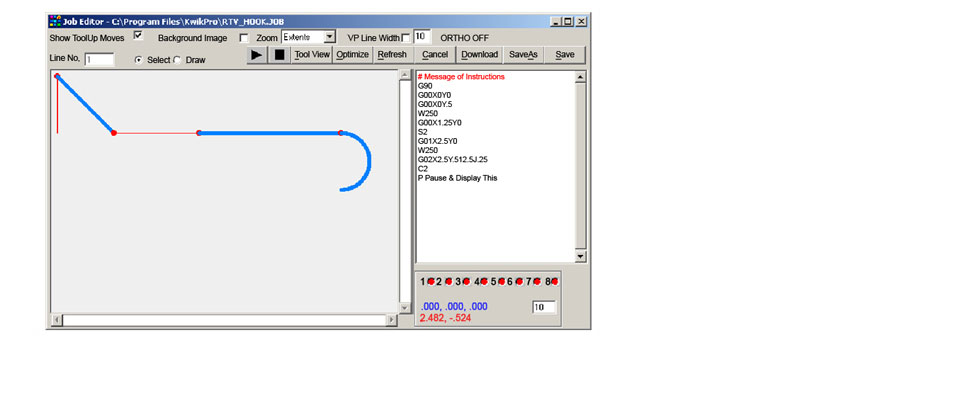

Build your dispense path / program with the dynamic editor. Draws the path as you type it or as you teach it directly from the machine.

With the advanced Jog & Teach function, the path will be drawn in real time as you teach it on the machine, creating a legitimate motion file that may be saved or edited.

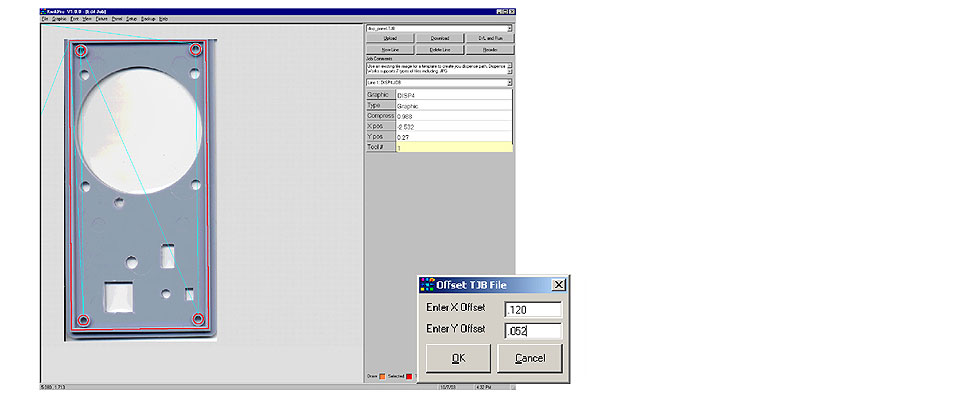

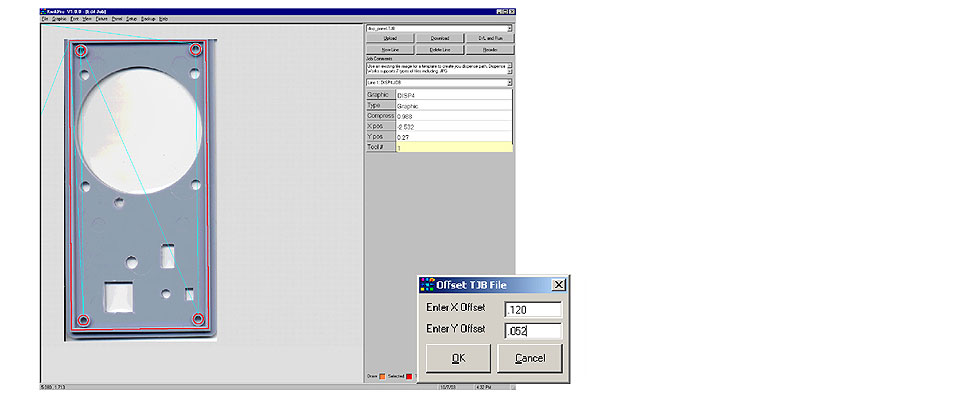

Visual Pattern Layout Screen

Import images of your parts and use them for a template to set up your dispensing pattern.

Supports .BMP .JPG .WMF .ICO .EMF .RLE .GIF

Tools are included to "fine tune" positions, scaling, etc.

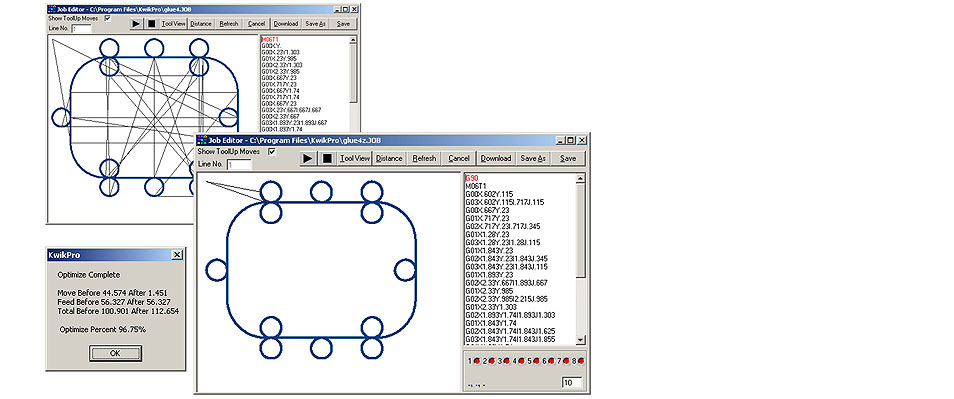

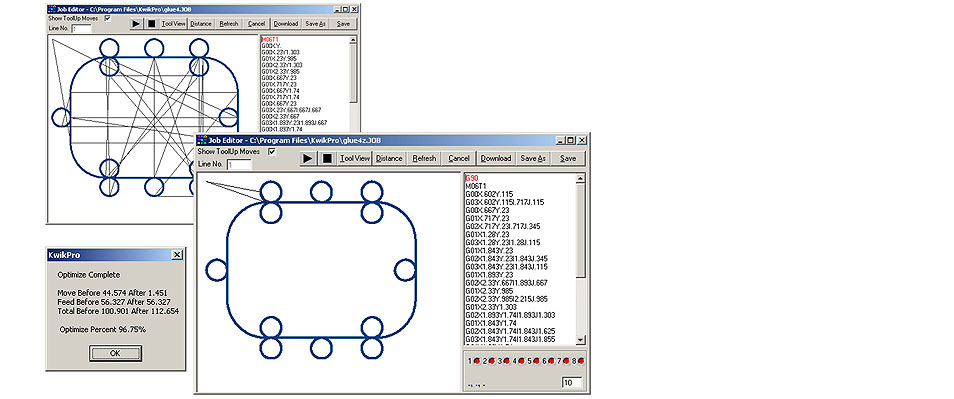

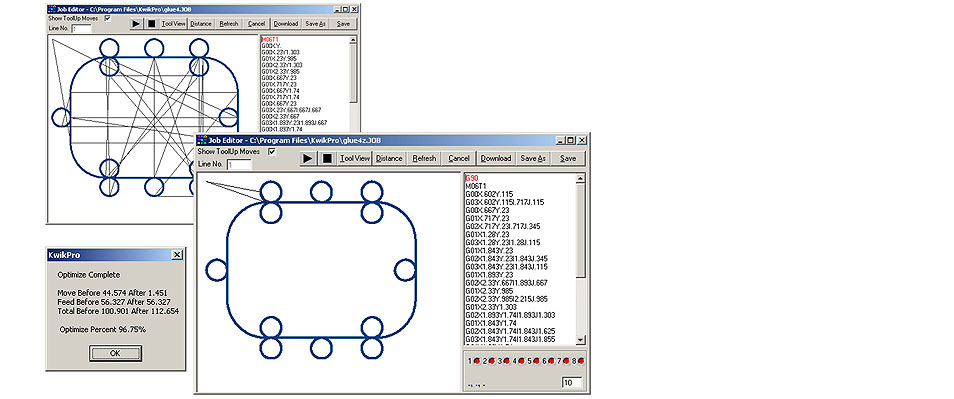

Optimize Motion Path Function

Top Left image is imported from a “raw” DXF file. Note the erratic motions. The Optimize function will redraw the image “looking ahead” to connect points for a logical continuous contouring motion. The algorithm will also control the connected circles to execute in CW and CCW motion for no change in velocity during the dispensing cycle. Furthermore, the program is greatly shortened.

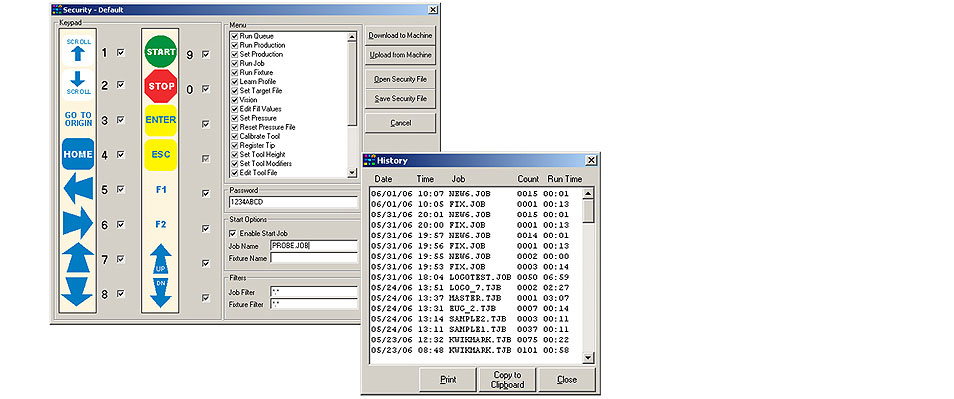

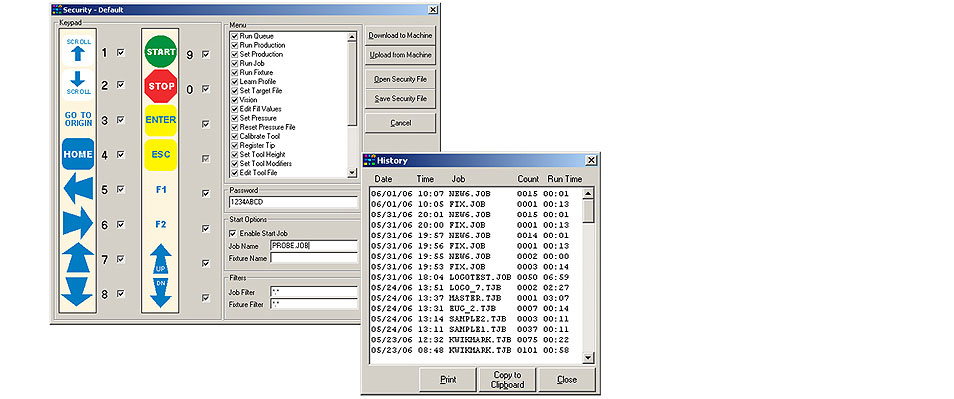

Security and History Files

Security File

The security file can be set to disable any menu entry or key function. All programs and settings are protected. This file is configurable and password protected. Several security files may exist.

History File

A convenient on-board history file displays detailed production information at the touch of a button. A copy/paste function is included for reporting.

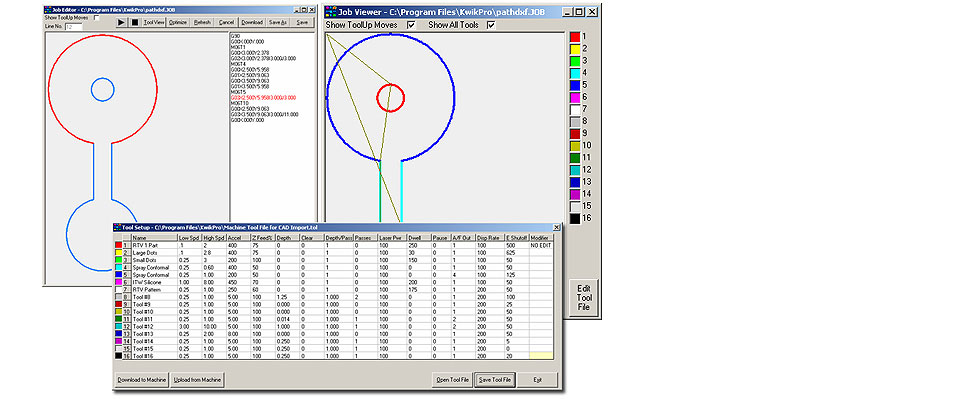

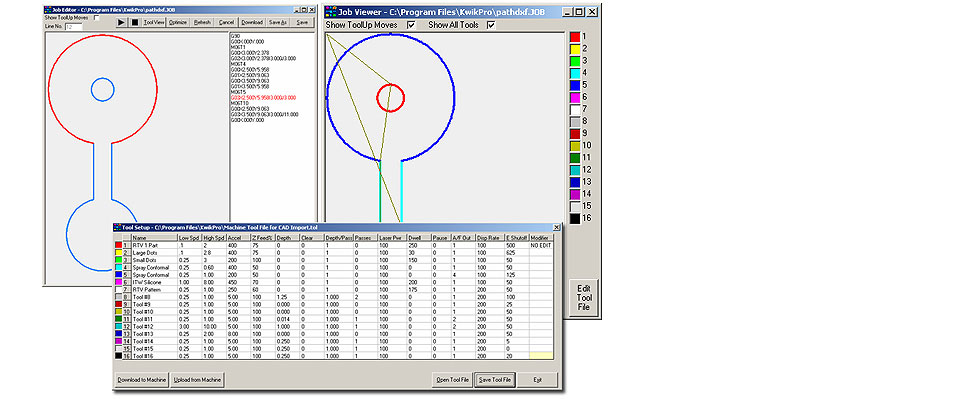

Control Properties by Color

Includes a full featured graphic viewer and editor. This means fast and simple creation and modification of the dispense path. Properties and events such as speed, tip height, valve timing, etc. are settable for each color or layer.

Programmable Pressure Files

Control dispensing pressure in absolute time to compensate for material’s varying viscosity.

The machine will display the expiration time remaining on the third line of the LCD display.

Latest Embedded Technology

Modular Construction

The system includes an embedded (dual memory) processor and CF memory card for true multi-tasking & real time performance. The machine is connectable to your network (LAN) or RS-232. Hundreds of files may be stored on the machine for quick changeover. Built-in step & repeat “Pallet” files simplify setups. Bar code scanner input will allow selecting jobs from a label or work order.

A True File Based Solution

“Your machine will be better tomorrow than it is today”

The ability to upgrade the machine’s software by downloading a single file, ensures that your investment will be as prudent as it is productive.

Built-In Digital Valve Controller

No external valve/syringe controller is required. This means much faster response times and control because all motion patterns and valves are controlled in “real time” from the main program. Furthermore, editing or modifying a program is all done in one file.

Pre-Programmed Functions

Simple & Powerful Graphical Programming

If connected to a PC, the dynamic screen displays the actual path (in real time) being taught with the machine. When saved, it is an authentic G-Code file that may be edited. A rich list of simple 2 letter commands are provided for controlling logic, external I/O and parameters. Hundreds of dispensing path files may exist in the machine.

Jog & Teach Path w/3-D

The advanced Jog & Teach function lets you “teach” the dispense path automatically by jogging the tip right over your part and capturing lines, arcs, circles, dots, etc. This becomes a legitimate path file which may be saved and edited.